It's

the world's most popular building material, and ever since the Romans

built the pantheon from it some 2,000 years ago, we've been trying to

find ways to make concrete more durable.

It's

the world's most popular building material, and ever since the Romans

built the pantheon from it some 2,000 years ago, we've been trying to

find ways to make concrete more durable.

No

matter how carefully it is mixed or reinforced, all concrete eventually

cracks, and under some conditions, those cracks can lead to collapse.

"The

problem with cracks in concrete is leakage," explains professor Henk

Jonkers, of Delft University of Technology, in the Netherlands.

"If

you have cracks, water comes through -- in your basements, in a parking

garage. Secondly, if this water gets to the steel reinforcements -- in

concrete we have all these steel rebars -- if they corrode, the

structure collapses."

But Jonkers has come up with an entirely new way of giving concrete a longer life.

"We have invented bioconcrete -- that's concrete that heals itself using bacteria," he says.

Concrete that can heal itself

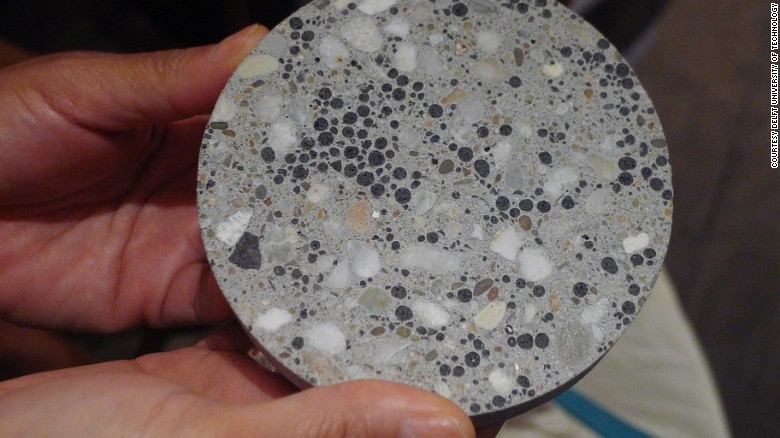

The

bioconcrete is mixed just like regular concrete, but with an extra

ingredient -- the "healing agent." It remains intact during mixing, only

dissolving and becoming active if the concrete cracks and water gets

in.

Jonkers, a microbiologist, began

working on it in 2006, when a concrete technologist asked him if it

would be possible to use bacteria to make self-healing concrete.

It took Jonkers three years to crack the problem -- but there were some tricky challenges to overcome.

"You

need bacteria that can survive the harsh environment of concrete," says

Jonkers. "It's a rock-like, stone-like material, very dry."

Concrete is extremely alkaline and the "healing" bacteria must wait dormant for years before being activated by water.

Jonkers

chose bacillus bacteria for the job, because they thrive in alkaline

conditions and produce spores that can survive for decades without food

or oxygen.

"The next challenge was not

only to have the bacteria active in concrete, but also to make them

produce repair material for the concrete -- and that is limestone,"

Jonkers explains.

In order to produce

limestone the bacilli need a food source. Sugar was one option, but

adding sugar to the mix would create soft, weak, concrete.

In

the end, Jonkers chose calcium lactate, setting the bacteria and

calcium lactate into capsules made from biodegradable plastic and adding

the capsules to the wet concrete mix.

When cracks eventually begin to form in the concrete, water enters and open the capsules.

The

bacteria then germinate, multiply and feed on the lactate, and in doing

so they combine the calcium with carbonate ions to form calcite, or

limestone, which closes up the cracks.

Now Jonkers hopes his concrete could be the start of a new age of biological buildings.

"It

is combining nature with construction materials," he says. "Nature is

supplying us a lot of functionality for free -- in this case,

limestone-producing bacteria.

If we

can implement it in materials, we can really benefit from it, so I think

it's a really nice example of tying nature and the built environments

together in one new concept."

No comments:

Post a Comment